- Description

- Technical Data

- Equipment: Base/Base addition

- Equipment: Reservoir

- Equipment: Drive

- Equipment: Nozzles

- Equipment: Options

Airless system for intervalled application of runny liquids from a distance without the addition of air.

Main application range:

External MQL in simple, metal-cutting and chipless forming operations.

Operating principle:

The liquid flows out of the reservoir into the piston chamber. The piston is accelerated by means of a compressed air impulse and shoots the liquid at high pressure through the nozzle.

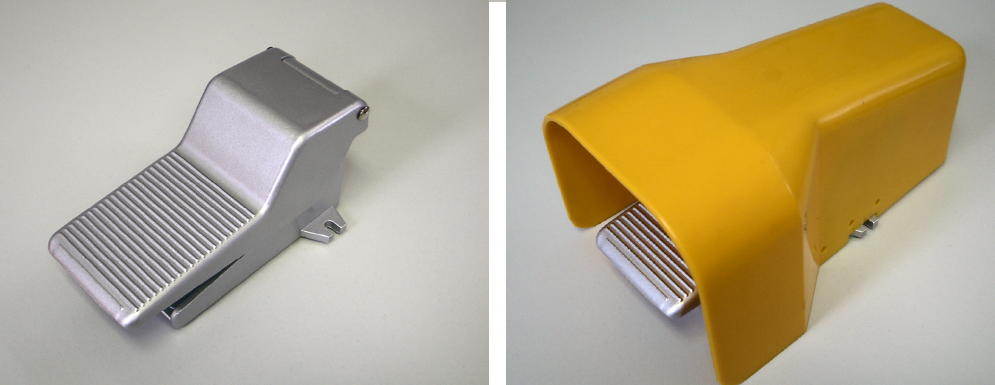

Version: P35/1-Y03-GLV-SH3 Version: P35/1- -V-SH3

Adjustability

-

Quantity of liquid (manual) at the PMC dial

-

Optional: Pressure of piston actuation air (manual)

-

Switch on/off using actuation control drive (electric, pneumatic or manual)

| Term | Figure | Unit |

|---|---|---|

| Operating pressure | 3 - 8 | bar |

| Max. dosage quantety | 0.06* for P35/1 0.12* for P35/1(4DF) | ml/h per stroke |

| Lubricoolant | Lubrimax® and others | |

| Recommended viscosity | 1 - 50** | mm²/s (at 40°C) |

| Max. distance | 750* | mm |

| Dimensions | WØxL | Unit |

|---|---|---|

| Base unit (without reservoir) P35/1-...-V | Ø 40 x 135 | mm |

| Base unit (without reservoir) P35/1-...-GLV | Ø 40 x 270 | mm |

* maximum values refer to water as fluid

** depending on application, operating pressure, fluid and dosage quantety

(from 0.33 to 27 litres available)

Unit assembly

Wall mounted reservoirs

(electric, pneumatic or pedal-operated option)

(options)

- Stand with switchable block magnet (55x50x80) or round magnet Ø80 and with articulated bar (Lmax=250).

- Pressure reducing valve including manometer for improved regulation of spray distance and profile.