- Brief description

- PAF Information

- PAF advantages

- Equipment: Base/Base addition

- Equipment: Drive

- Equipment: Hoses

- Equipment: Options

- Technical Data

Unit for permanent, automatic refilling of fluids in small quantities.

PAF is a space-saving unit for the transportation of liquids of a container in another one, also about larger heights or distances.

Main application range:

Filling-up of reservoirs from MQL units.

Operating principle:

A piston pump sucks the fluid from an unpressurized container into a reservoir.

Adjustability

-

-

The factory setting determines the flow rate (manually adaptable)

-

PAF has been developed especially for the reduced outputs and smaller reservoir dimensions of minimum quantity lubrication (MQL)

A low, but permanent volume flow prevents the reservoir from overfilling or the foam up of the fluid. PAF makes the refilling of inaccessible containers easier, extends the stock volume, raises the process reliability and allows a consumption control.

The powerful, self-priming piston pump of the PAF lifts fluids up to 2-m (e.g., from a container or drum) and then pumps the fluid up to 4-m height, also over a distance of up to 20 m. The pre-set output volume is 360ml/hour. PAF can pump fluids also against a pressure up to 5 bars (an integrated safety valve protects you against dangers of a too big counter pressure).

Normally PAF is actuated by an electric signal (e.g., from the machine control / PLC). On demand a purely pneumatic version is also available.

The typical area of application of PAF is the permanent, automatic refilling of reservoirs of MQL units. But PAF is also applicable in any case where an automatic transport / dosing of fluids in small quantities over a longer period is needed.

PAF increases the productivity

-

-

by reduced workload of the machine operator (automatic refilling)

-

by refilling also during night/unmanned shifts

-

by filling of pressurized reservoirs (up to 5bars) also during operation

-

in case of too small designed reservoirs (e.g., narrow assembly space)

-

PAF increases the process reliability by

-

-

permanent, automated refilling

-

an additional stock volume (redundancy)

-

the possibility of a consumption volume control

-

the controlled dosing of a fluid component (e.g., water mixable concentrates)

-

PAF increases the working security

-

-

at difficult accessable / ergonomically unfavorably mounted reservoirs

-

at reservoirs mounted within the danger / restricted zone

-

in case of optional purely pneumatic operation => no electronic components

-

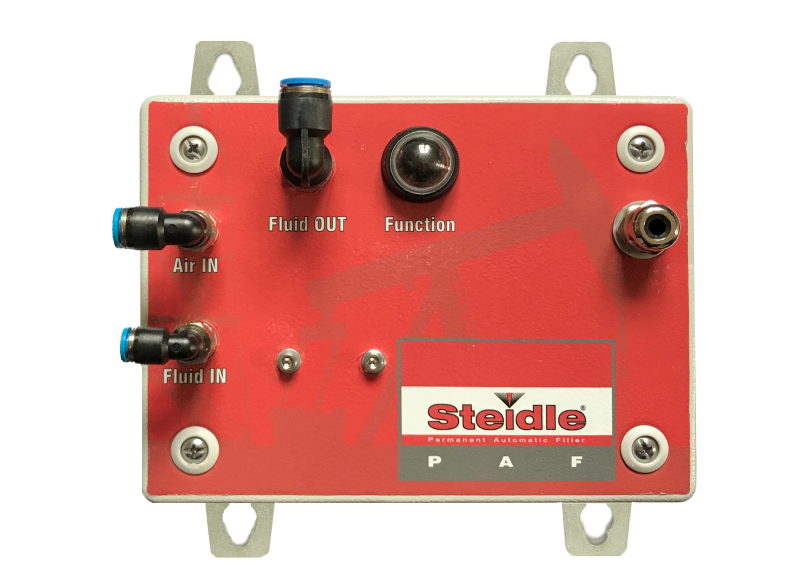

Drive electric or pneumatic option:

- Electric solenoid valve (3/2 ways, 120Nl / min) with auxiliary overdrive (for occasional manual actuation) with coil / plug in 24VDC, 110VAC or 230VAC. Cable bushing with strain relief.

- Pneumatic actuation via compressed air input.

Installation

- Housing mounting straps, 4x

- Housing mounting, 2x round magnets Ø80, diagonal on backside

- Housing mounting, 1x round magnet Ø80, on the underside

| Operating pressure | bar | 4 – 8 |

| Dosage quantity | ml/h | 360 |

| Max. suction height | m | 2 |

| Max. pump height | m | 4 |

| Max. pump distance | m | 20 |

| Recommended viscosity | mm²/s (at 40°C) | <230 |

| Air consumption | Nl/min | 8 |

| Power consumption | W/h | 1.5 |

| WxHxD | mm | 300x150x80 |